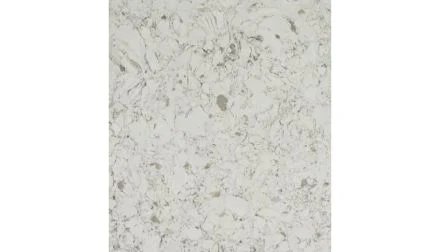

Hotel House Decorative Yellow/Honey/Blue/Black/Pink/Green/White/Cream/Blue/Orange Natural Stone Onyx for Wall and Flooring

Basic Info.

| Slab Size | 1400up*2600up mm |

| Sample | Small Free Provide |

| Material Assurance | 100% Natural Marble Onyx |

| Form | Tile,Polished Tile,Big Slab,Porcelain Tiles,Interi |

| Used for | Villa,Hotel,Super Building,Home Decoration,Floor |

| Transport Package | Strong Wooden Pallet |

| Specification | as customized |

| Trademark | Tianyuan stone |

| Origin | China |

| HS Code | 68029190 |

| Production Capacity | 10000 Square Meter Per Month Decorat |

Product Description

Hotel house decorative Yellow/Honey/Blue/black/Pink/Green/White/cream/blue/Orange Natural Stone Onyx for Wall and FlooringProduct | onyx for background wall |

| About Us | 1) We have been concentrating on stone industry for more than 15 years. 2) Own quarry and full equipped processing machines. 3) Experienced workers and efficient management team |

| Size | ♦ Tile Size 1) 305 x 305 x 10mm or 12" x 12" x 3/8" 2) 400 x 400 x 12mm or 16" x 16" x 1/2" 3) 457 x 457 x 12mm or 18" x 18" x 1/2" 4) 600 x 600 x 20mm or 24" x 24" x 3/4" 5) Cut-to-size or any other customized sizes ♦Slab Size: 1200 up*2400 up*20/30mm ♦Half Slab Size: 600*1800 up*20/30mm; 700*1800 up*20/30mm |

| Quality Control | 1) Polished degree: 85 or up 2) Thickness tolerance: -2/+1mm QC check pieces by pieces strictly before packing. 3) Diagonal tolerance : +/-1mm 4) Surface flatness tolerance: +/-0.3mm 5) Adjacent edge verticality tolerance: +/-0.5mm, Precise Cutting by infrared-ray-cut machine |

Packing & Delivery | ♦ Packing Detail 1) Inner packing: Cartons or foamed plastics (polystyrene). 2) Out packing:Seaworthy wooden crated with fumigation. ♦ Delivery Detail 1) Delivery Time: 10~15 days after the order confirmed. 2) Shipping Port: Xiamen Port, China |

| Payment | 1) 30% T/T advance payment and balance 70% T/T bfore or against B/L Copy 2) Other payment terms are available after negotiation. |

Offer Various kinds of stone,welcome to ask inquiry, save your cost

If you want more clear pictures,pls contact us.Acutal stone are more beautiful than photos

More onyx colors

Packing: Fumigated ocean wooden crates or pallets,also can be packed as per your demand, all wood is fumigated as per

current international requirements ISPM16.

1)Tile(thickness 1cm or 1.2cm) 800 - 1000 m2/ container(27t).

put tiles in a paper box, then put boxes in a wooden crate which padded with formed plastic and packing it.

2)Tile(thickness 1.5cm and up) 200 - 600 m2/container(27t).

put tiles in a wooden crate(with polished face to face) which padded with formed plastic and packing it.

3)Slabs: Slabs will be packed in a wooden bundles with polished face to face.

Our strict quality control for marble tiles. The following aspects are covered under marble inspection:

1. Checking for texture, color, spots, color lines and grainy/uniform crystal structure.

2. Inspection of surface finish - honed, flamed, polished, tumbled, bush hammered or more.

3. Checking for visible defects like scratches, broken edges, cracks, chipping, etching, pin holes, repair marks, swirl marks, etc.

4. Looking for other production defects, such as angle between adjacent edges, and intensity of polish and flatness.

5. Checking the length, thickness and width of the marble tile as per the specification or within the acceptable tolerance along

with diagonal length and angle control

.

Thin tiles are packed every 8 pcs per carton or foam boxes, and then in strong wooden crates.

Thick tiles are packed directly in wooden crates, with safe support to protect the surface& edges, and prevent rain and dust.

Slabs are packed in strong wooden bundles.